From:

In: BRICK. SPECIAL ISSUES ON ST. LOUIS, MAY AND JUNE 1904

May, 1904, p. 232-233. Vol. XX, No. 5

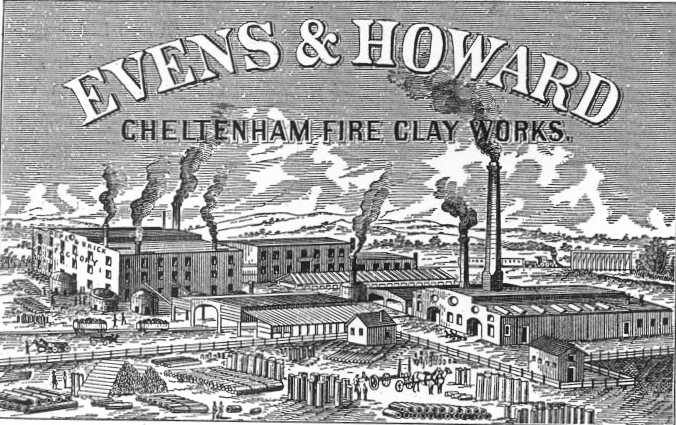

NOTE: THE DRAWING OF THE PLANT IS NOT FROM BRICK MAGAZINE. I CAN'T RECALL WHERE I GOT THIS DRAWING.

Pursuing our way still further down the firing line we come to the plant of the Evens & Howard Fire Brick co. This is one of the oldest clay working plants in St. Louis. Operations were commenced here on the same site in the year of 1855, the business being then known as the Cheltenham Fireclay Works. The history of the plant is an interesting one, for the pioneers of the enterprise, J.C. Evens and R. J. Howard steadily pushed their products into distant fields until the Evens & Howard fire brick acquired a national reputation. It would be difficult to state how wide an area of shipment is covered by products of the plant. But in looking through some old newspaper clippings we came across an interesting shipment made in 1891, of fire brick to an india rubber factory in the interior of Africa. The brick was shipped via new Orleans to the west coast of Africa and then carried overland 400 miles into the interior. Each brick was stamped with the name Evens & Howard, and future explorers or antiquarians will in time to come perhaps discuss the existence of this brick in such a remote place as a positive evidence that the early African tribes possessed a high degree of manufacturing dexterity and knowledge.

The grounds of the plant cover 133 acres. The company has three mines in the city and one mine at Glencoe, Mo., 30 miles away, where about 61 acres are owned. All the mining is done below ground by pick and blast. About 50 men are constantly employed disembowelling the raw material. The company has an extensive equipment of cars and tracks, at Glencoe, for the conveying of the clay to the plant. All clay is weathered for at least six months. The clay from the mines on the plant is hauled to the dry pay by teams, being dumped into storage bins situated near the pans for which it is intended.

As seen by our illustrations the works has an enormous frontage and comprises on plant No. 1, three main buildings facing Manchester Ave. These building are connected by covered bridges forming a continuous building 500 ft. long and four stories high. These three buildings are devoted entirely to sewer pipe. On the main floor are to be found six 9-ft. pans, four of them wet pans and two dry pans. From the dry pans the ground material is elevated by bucket elevator to Dunlap screens, located on a fifth story elevation. These have a screening capacity of 150 tons daily, the clay processing from them to storage bins on the first floor. From these bins the clay is delivered by a chute to the wet pans, from which it is taken by conveyor and elevator to Turner, Vaugh & Taylor sewer pipe presses on the second, third and fourth floors. The pipe is made in all sizes ranging from 3-in. to 36-in. On these same presses are also made wall coping, drain tile and fireproofing. As many as 145 tons a day of pipes of various sizes are made. All traps are made by hand, and on the fourth floor are manufactured the joints and Y-connections. Finishing is also done on this floor. On every floor is an enormous drying space, the heat being furnished by exhaust steam from the engine threading its way through miles of steam pipes.

A power pipe turner is used for pipe above 21 in. in diameter, while the smaller pipe is turned by an ingenious hand turner of the company's own construction. The pipe are handler in the kilns by derricks operated by compressed air and a Westinghouse pump. This is used for both setting and drawing.

There are 22 down-draft kilns, ranging from 25 to 30 ft. in diameter. The kilns run parallel with the building, the pipes being skidded from floor to floor above the second story, and from the second story straight into the door of the kilns by the chute. The large size pipes are ready for the kilns in about two weeks, while the smaller pipes are dried in about two days. Watersmoking and burning are done with coal, three days being allowed for watersmoking and four for burning. About 10 or 12 kilns are on fire at one time. The cooling off requires three days, when the kiln is drawn and the pipe conveyed by wagons to the stock piles.

The power equipment comprises a 250 h.p. St. Louis-Corliss engine and a small engine to run the machine shop. The machine shop is well equipped with planers, lathes, drill presses, and emery grinders, the company doing all its own work, except the making of large castings. The main portions of the plant are supplied with electric light.

At the rear of the large sewer pipe plant is situated the brick plant, the main building of which is four stories in height, and 200 x 130 ft. The clay for this product is obtained from the mines on the plant, from which are taken about 400 tons of fireclay daily. The pan equipment consists of three 9-ft. dry pans, and two 9-ft. wet pans. The material proceeds from these to a Dunlap screen on the fourth floor, from which it passes to the storage bins on the third floor. From these bins the clays are drawn as desired. If for the manufacture of stiff-mud firebrick the clay passes into a mixer on the second floor and then into a brick machine of 600,000 daily capacity on the first floor. The whole machine equipment was supplied by the American Clay Working Machinery Co., of Bucyrus, O. From the cutting table the brick proceed into an exhaust steam drier. from which they emerge in from 36 to 48 hrs. They are then trucked to the kilns. There are 13 kilns of the same type and range of capacity as those on No. 1 plant, the watersmoking and burning being done with the same fuel and in the same time.

Five Miller hand presses, each making about 4,000 brick daily, are used for special firebrick work. The wet pans supply the material for the special tiles manufactured on the second, third and fourth floors. The Evens & Howard Co. devotes considerable attention to the manufacture of tiles for their own work, supplying refractory products to trade demanding those of the highest grade. Besides this work many kinds of tile are made for private concerns. An immense stock is kept on hand of refractory tile and block for locomotives, smelters, furnace work, etc. The shipments arc extensive, as many as 30 cars a day being loaded and dispatched. About 450 men are employed on the plant, and the work is carried on the year through.

W. J. Hemphill, the general manager, has been four years with the company, was previously master mechanic for the Chicago & Alton R.R., and has also filled a similar position on the Union Pacific. His longer experience in railroad work has stood him in good service in his present positions, and many of the devices on the plant are the products of his mechanical skill and knowledge.

Such an extensive plant, of course, requires a well organized force to effect the most economical and rapid manufacturing operations. There is a superintendent of the pipe department, a superintendent of the brick department, a superintendent of each mine, and each superintendent has a foreman under him. The company find a ready market for its brick in St. Louis, and for the adequate handling of this large down-town business forty horses are kept, housed in commodious stables.

The officers of the company are: President, Cecil D. Gregg; vice-president, Andrew Sproule; secretary, Geo. W. Jones, and assistant secretary, F.E. Rhoads.

The appearance of the plant from a distance is a very imposing one as will readily be seen from the accompanying illustration. The tall stacks belch out volumes of smoke, which, united on damp days, form a huge canopy above the plant. The stacks are of brick, 75 ft. in height, and supply draft to two or four kilns, as required. Besides the equipment already mentioned the plant has many up-to-date contrivances for the lightening of labor and lessening of the cost of manufacture. The plant is well worth a visit and can be reached from down town most readily by taking a Laclede car at the Union station and transferring to a Suburban car. The shipping facilities of the plant are over Missouri Pacific and Frisco railroads. The company has very fine downtown offices in a neat brick structure erected and owned by the company at 920 Market St.

| HOME | DOGTOWN |

| Bibliography | Oral history | Recorded history | Photos |

| YOUR page | External links | Walking Tour |