Source, details and fireclay story below photo.

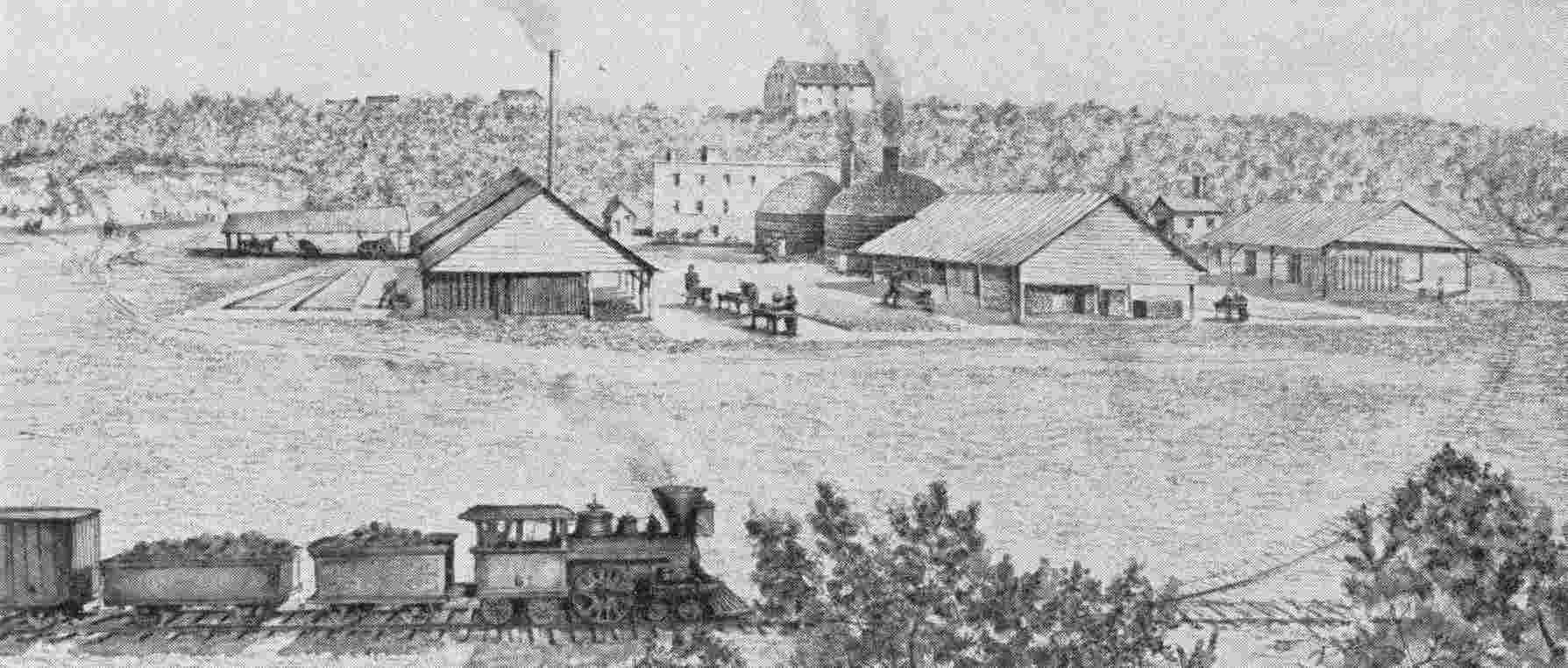

This is the Laclede Brick Comany in 1854. Up on the hill above it is the old Sublette home, which, just four years after this drawing would have been inhabited by the Icarians. It would be in the middle of I-44 now. For more on the Icarian movement, click here.

The photo is taken from page 6 of: Anon. FIRECLAY REFRACTORIES. St. Louis: Laclede-Christy Clay Products Company, 1947.

The book is a catalogue of their products. However, under the above photo the

do offer this bit about the company:

"Laclede Fire Brick Manufacturing Company was founded in 1844 as one of the earliest manufacturers of

fireclay brick in the United States. The plant was located in St. Louis because of the abundance

of Cheltenham fireclay which has later proven one of the most desirable raw materials for the

manufacture of fireclay refractories.

"IN 1856 the Christy Fireclay Company was founded in St. Louis, and from the beginning specialized in the manufature of fireclay refractories for the glass industry. In 1907 the Laclede Fire Brick Manufacturing Company and the Christy Fireclay Company were consolidated and incorporated under the laws of the state of Missouri as the Laclede-Christy Clay Products Company."

NOTE on page 10 the "refractory" concept is explained: "Refractory, as applied to industrial products, normally is taken to mean "resistant to high temperatures." The term usually implies a product suitable for lining industrial furnaces in which either combustion or some process requiring high temperatures takes place. While a refractory must resist high temperatures, there are other requirements it must fulfill.

"In almost all industrial furnaces the action of heat is combined with chemical reactions, and we have what the refractory engineer calls slag action. In addition, temperatrues are not constant, which gives the added problem of temperature fluctuations. Finally, some strictly mechanical action may be taking place in the furnace, and this will add abrasion to the destructive forces to which the refractory lining is exposed. It becomes evident, therefore, that the term, refractory, comes to mean a product which will resist some or all of these destructive actions in order to be suitable for lining industrial furnaces. The most universally used refractories are fireclay brick and tile."

| HOME | DOGTOWN |

| Bibliography | Oral history | Recorded history | Photos |

| YOUR page | External links | Walking Tour |